新疆农业科学 ›› 2024, Vol. 61 ›› Issue (2): 345-354.DOI: 10.6048/j.issn.1001-4330.2024.02.010

马云龙1,2( ), 谢辉2, 张雯2, 朱学慧2,3, 王艳蒙2,3, 麦斯乐2,3, 张佳喜1(

), 谢辉2, 张雯2, 朱学慧2,3, 王艳蒙2,3, 麦斯乐2,3, 张佳喜1( )

)

收稿日期:2023-06-18

出版日期:2024-02-20

发布日期:2024-03-19

通信作者:

张佳喜(1973-),男,研究员,研究方向为农牧业机械,(E-mail)563810112@qq.com作者简介:马云龙(1996-),男,硕士研究生,研究方向为果蔬干燥,(E-mail)1286001135@qq.com

基金资助:

MA Yunlong1,2( ), XIE Hui2, ZHANG Wen2, ZHU Xuehui2,3, WANG Yanmeng2,3, MAI Sile2,3, ZHANG Jiaxi1(

), XIE Hui2, ZHANG Wen2, ZHU Xuehui2,3, WANG Yanmeng2,3, MAI Sile2,3, ZHANG Jiaxi1( )

)

Received:2023-06-18

Published:2024-02-20

Online:2024-03-19

Supported by:摘要:

【目的】研究不同温度条件下热风干燥对葡萄干色泽相关指标、水分扩散系数的影响,为绿色葡萄干的工业化生产加工提供理论和技术支撑。【方法】采用不同温度(30、32.5、35、37.5和40℃)对无核白葡萄进行干燥,分析温度对葡萄色泽、水分扩散系数及制干品质的影响,拟合干燥动力学模型。【结果】干燥温度为35℃时绿色葡萄干比率最高达到64%,色泽与原料的差异最小,色差ΔE仅为6.99,C、h0、L、a、b等色泽指标分别为18.23、1.4、14.57、2.99、17.95。叶绿素、叶绿素a、叶绿素b、类胡萝卜素、总酚含量分别为0.56、0.19、0.36、0.32、0.18 mg/g。35℃更适宜绿色葡萄干加工。最符合葡萄干燥的模型,决定系数 R2值最大,误差平方和、SSE和均方根误差RMSE均值最小,分别为 0.998 1、0.005 4和 0.007 7。绿色葡萄干最适宜的有效水分扩散系数为5.334 8×10-9。【结论】热风干燥温度为35℃时最有利于无核白绿色葡萄制干,35℃时有效水分扩散系数分别为30、32.5、37.5和40℃的114.13%、110.58%、95.17%和76.58%,Logarithmic 模型可以有效的描述热风干燥工艺条件下葡萄果实水分的变化规律。

中图分类号:

马云龙, 谢辉, 张雯, 朱学慧, 王艳蒙, 麦斯乐, 张佳喜. 温度对绿色葡萄干色泽及干燥特性的影响[J]. 新疆农业科学, 2024, 61(2): 345-354.

MA Yunlong, XIE Hui, ZHANG Wen, ZHU Xuehui, WANG Yanmeng, MAI Sile, ZHANG Jiaxi. Effects of temperature on color and drying characteristics of green raisins[J]. Xinjiang Agricultural Sciences, 2024, 61(2): 345-354.

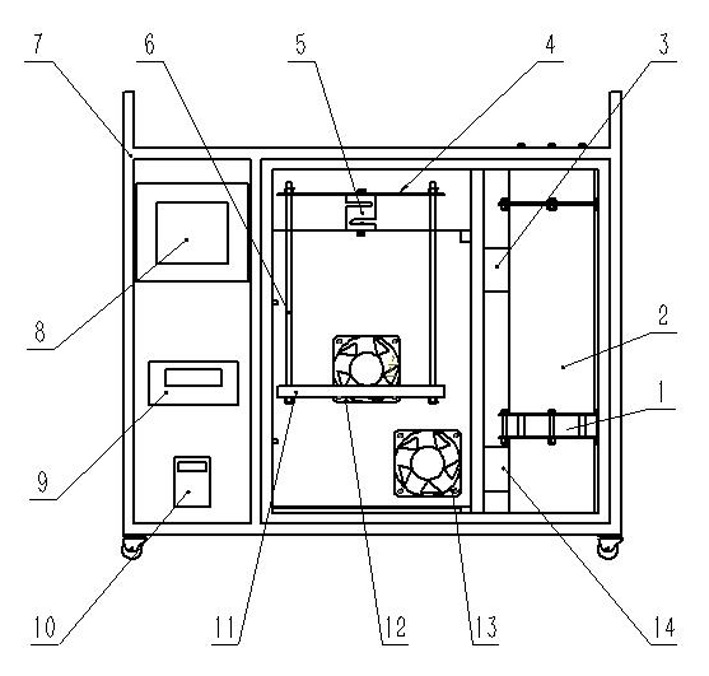

图1 干燥装置结构 注:1.风机;2.加热装置;3.入风口;4.平衡板;5.称重传感器;6.螺纹杆;7.机架;8.触摸屏;9.重量数显;10.变频器;11.托盘;12.风机;13.风机;14.回风口

Fig.1 Structure diagram of drying device Note:1.Fan;2.Heating device;3.Air Intake;4.Balance board;5.Weighing sensor;6.Screw rod;7.Rack;8.Touch screen;9.Weight digital display;10.Frequency converter;11.Tray;12.Fan;13.Fan;14.ari outlet

| 序号No. | 模型名称Model name | 模型公式Model equation |

|---|---|---|

| 1 | Weibull | MR=exp(-(t/b)a) |

| 2 | Henderson and pabis | MR=aexp(-kt) |

| 3 | Logarithmic model | MR=aexp(-kt)+c |

| 4 | Midilli et al. | MR=aexp(-ktn)+bt |

| 5 | Modified enderson and pabis | MR=aexp(-kt)+bexp(-gt)+cexp(+ht) |

| 6 | Newton(single-term exponential) | MR=exp(-kt) |

| 7 | Page | MR=exp(-ktn) |

| 8 | Two-term Logarithmic model | MR=aexp(-k0t)+bexp(-k1t) |

| 9 | Verma et al. | MR=aexp(-kt)+(1-a)exp(-gt) |

| 10 | Wang and singh | MR=1+at+bt2 |

表1 常见10种干燥模型

Tab.1 Common 10 drying models

| 序号No. | 模型名称Model name | 模型公式Model equation |

|---|---|---|

| 1 | Weibull | MR=exp(-(t/b)a) |

| 2 | Henderson and pabis | MR=aexp(-kt) |

| 3 | Logarithmic model | MR=aexp(-kt)+c |

| 4 | Midilli et al. | MR=aexp(-ktn)+bt |

| 5 | Modified enderson and pabis | MR=aexp(-kt)+bexp(-gt)+cexp(+ht) |

| 6 | Newton(single-term exponential) | MR=exp(-kt) |

| 7 | Page | MR=exp(-ktn) |

| 8 | Two-term Logarithmic model | MR=aexp(-k0t)+bexp(-k1t) |

| 9 | Verma et al. | MR=aexp(-kt)+(1-a)exp(-gt) |

| 10 | Wang and singh | MR=1+at+bt2 |

| 温度 Temperature (℃) | L | a | b | ΔE | C | h0 | 绿品率 Green rate (%) |

|---|---|---|---|---|---|---|---|

| 30 | 5.77±4.81c | 5.82±1.13a | 10.47±4.73c | 16.80±5.11a | 12.15±4.39c | 1.01±0.17b | 0.41±0.03c |

| 32.5 | 9.38±4.27b | 3.15±4.38a | 16.50±2.52b | 11.92±3.92b | 17.26±3.16b | 0.99±0.64b | 0.43±0.04c |

| 35 | 14.56±3.25a | 2.98±1.06a | 17.94±2.37b | 6.99±2.72c | 18.23±2.31b | 1.40±0.07a | 0.64±0.02a |

| 37.5 | 11.41±2.8b | 3.96±1.76a | 20.56±3.07a | 11.05±1.53b | 21.04±2.82a | 1.37±0.10a | 0.54±0.03b |

| 40 | 10.68±4.64b | 5.00±6.45a | 16.04±4.43b | 13.22±3.5b | 17.69±5.42b | 0.87±0.58b | 0.46±0.01c |

表2 不同温度条件下色泽指标

Tab.2 Color index at different temperature

| 温度 Temperature (℃) | L | a | b | ΔE | C | h0 | 绿品率 Green rate (%) |

|---|---|---|---|---|---|---|---|

| 30 | 5.77±4.81c | 5.82±1.13a | 10.47±4.73c | 16.80±5.11a | 12.15±4.39c | 1.01±0.17b | 0.41±0.03c |

| 32.5 | 9.38±4.27b | 3.15±4.38a | 16.50±2.52b | 11.92±3.92b | 17.26±3.16b | 0.99±0.64b | 0.43±0.04c |

| 35 | 14.56±3.25a | 2.98±1.06a | 17.94±2.37b | 6.99±2.72c | 18.23±2.31b | 1.40±0.07a | 0.64±0.02a |

| 37.5 | 11.41±2.8b | 3.96±1.76a | 20.56±3.07a | 11.05±1.53b | 21.04±2.82a | 1.37±0.10a | 0.54±0.03b |

| 40 | 10.68±4.64b | 5.00±6.45a | 16.04±4.43b | 13.22±3.5b | 17.69±5.42b | 0.87±0.58b | 0.46±0.01c |

| 温度 Temperature (℃) | 叶绿素 Chlorophyll | 叶绿素a Chlorophyll a | 叶绿素b Chlorophyll b | 类胡萝卜素 Carotenoid | 总酚 Total phenols |

|---|---|---|---|---|---|

| 30 | 0.37±0.01d | 0.13±0.01d | 0.23±0.01d | 0.70±0.04c | 0.30±0.07a |

| 32.5 | 0.42±0.01c | 0.15±0.01c | 0.27±0.01c | 0.81±0.03b | 0.25±0.13b |

| 35 | 0.55±0.03a | 0.19±0.01a | 0.36±0.02a | 0.94±0.02a | 0.15±0.12d |

| 37.5 | 0.47±0.01b | 0.17±0.01b | 0.30±0.01b | 0.72±0.01c | 0.19±0.07c |

| 40 | 0.39±0.01d | 0.14±0.01d | 0.25±0.01d | 0.64±0.01d | 0.20±0.03c |

表3 不同温度下葡萄干叶绿素及总酚变化

Tab.3 Chlorophyll and total phenol of raisins at different temperatures

| 温度 Temperature (℃) | 叶绿素 Chlorophyll | 叶绿素a Chlorophyll a | 叶绿素b Chlorophyll b | 类胡萝卜素 Carotenoid | 总酚 Total phenols |

|---|---|---|---|---|---|

| 30 | 0.37±0.01d | 0.13±0.01d | 0.23±0.01d | 0.70±0.04c | 0.30±0.07a |

| 32.5 | 0.42±0.01c | 0.15±0.01c | 0.27±0.01c | 0.81±0.03b | 0.25±0.13b |

| 35 | 0.55±0.03a | 0.19±0.01a | 0.36±0.02a | 0.94±0.02a | 0.15±0.12d |

| 37.5 | 0.47±0.01b | 0.17±0.01b | 0.30±0.01b | 0.72±0.01c | 0.19±0.07c |

| 40 | 0.39±0.01d | 0.14±0.01d | 0.25±0.01d | 0.64±0.01d | 0.20±0.03c |

| 编号 No. | 模型名称 Name of model | 常数 Constant | 干燥温度 Drying conditions(℃) | ||||

|---|---|---|---|---|---|---|---|

| 30 | 32.5 | 35 | 37.5 | 40 | |||

| 1 | Weibull | a | 0.022 57 | 0.024 74 | 0.024 57 | 0.046 95 | 0.039 18 |

| b | 2.009 3 | 2.075 15 | 1.901 73 | 2.974 5 | 1.827 79 | ||

| 2 | Henderson and pabis | a | 1.097 12 | 1.095 35 | 1.109 92 | 1.078 42 | 1.039 05 |

| k | 0.012 33 | 0.013 07 | 0.014 34 | 0.017 03 | 0.022 25 | ||

| 3 | Logarithmic model | a | 1.357 4 | 1.334 | 1.362 69 | 1.198 53 | 1.089 04 |

| k | 0.006 93 | 0.007 6 | 0.008 2 | 0.012 09 | 0.017 99 | ||

| c | -0.330 68 | -0.305 37 | -0.321 54 | -0.166 53 | -0.083 12 | ||

| 4 | Midilli et al. | a | 1.026 72 | 1.449 3 | 1.041 14 | 1.433 48 | 1.009 93 |

| k | 2.722 0 | 0.032 05 | -0.504 1 | 0.507 8 | 0.003 2 | ||

| n | -5.738 15 | -5.716 08 | -5.721 61 | -5.592 83 | 0.032 05 | ||

| b | 0.001 71 | 0.001 54 | 0.001 97 | 0.001 83 | -4.570 2E-4 | ||

| 5 | Modified enderson and pabis | a | 0.365 72 | 0.365 12 | 0.369 98 | 0.359 47 | 0.595 32 |

| k | 0.012 33 | 0.013 07 | 0.014 34 | 0.017 03 | 0.087 43 | ||

| b | 0.365 72 | 0.365 12 | 0.369 98 | 0.359 47 | 22.164 49 | ||

| g | 0.012 33 | 0.013 07 | 0.014 34 | 0.017 03 | 0.039 35 | ||

| c | 0.365 72 | 0.365 12 | 0.369 98 | 0.359 47 | -21.762 84 | ||

| h | 0.012 33 | 0.013 07 | 0.014 34 | 0.017 03 | 0.041 42 | ||

| 6 | Newton | k | 0.011 23 | 0.011 92 | 0.012 92 | 0.015 78 | 0.021 44 |

| 7 | Page | k | -0.105 99 | -0.109 21 | -0.113 68 | -0.125 64 | 0.0188 5 |

| n | -0.105 99 | -0.109 21 | -0.113 68 | -0.125 64 | 1.137 07 | ||

| 8 | Two-term Logarithmic model | a | 0.548 56 | 0.547 69 | 0.554 95 | 0.539 2 | -18.800 28 |

| K0 | 0.012 33 | 0.013 07 | 0.014 34 | 0.017 03 | 0.035 68 | ||

| b | 0.548 56 | 0.547 69 | 0.554 95 | 0.539 2 | 19.773 3 | ||

| K1 | 0.012 33 | 0.013 07 | 0.014 34 | 1.017 03 | 0.034 56 | ||

| 9 | Verma et al. | a | 1.118 35 | 1.117 63 | 1.138 21 | 1.103 26 | 55.232 05 |

| k | 0.012 57 | 0.013 34 | 0.014 7 | 0.017 43 | 0.033 94 | ||

| g | 15.304 4 | 15.714 88 | 15.856 79 | 16.038 18 | 0.034 28 | ||

| 10 | Wang and singh | a | -0.008 1 | -0.008 67 | -0.009 32 | -0.011 82 | -0.015 47 |

| b | 1.58878E-5 | 1.84101E-5 | 2.09099E-5 | 3.61915E-5 | 6.1261E-5 | ||

表4 不同温度下10种模型拟合常数

Tab.4 The fitting constants of 10 models at different temperatures

| 编号 No. | 模型名称 Name of model | 常数 Constant | 干燥温度 Drying conditions(℃) | ||||

|---|---|---|---|---|---|---|---|

| 30 | 32.5 | 35 | 37.5 | 40 | |||

| 1 | Weibull | a | 0.022 57 | 0.024 74 | 0.024 57 | 0.046 95 | 0.039 18 |

| b | 2.009 3 | 2.075 15 | 1.901 73 | 2.974 5 | 1.827 79 | ||

| 2 | Henderson and pabis | a | 1.097 12 | 1.095 35 | 1.109 92 | 1.078 42 | 1.039 05 |

| k | 0.012 33 | 0.013 07 | 0.014 34 | 0.017 03 | 0.022 25 | ||

| 3 | Logarithmic model | a | 1.357 4 | 1.334 | 1.362 69 | 1.198 53 | 1.089 04 |

| k | 0.006 93 | 0.007 6 | 0.008 2 | 0.012 09 | 0.017 99 | ||

| c | -0.330 68 | -0.305 37 | -0.321 54 | -0.166 53 | -0.083 12 | ||

| 4 | Midilli et al. | a | 1.026 72 | 1.449 3 | 1.041 14 | 1.433 48 | 1.009 93 |

| k | 2.722 0 | 0.032 05 | -0.504 1 | 0.507 8 | 0.003 2 | ||

| n | -5.738 15 | -5.716 08 | -5.721 61 | -5.592 83 | 0.032 05 | ||

| b | 0.001 71 | 0.001 54 | 0.001 97 | 0.001 83 | -4.570 2E-4 | ||

| 5 | Modified enderson and pabis | a | 0.365 72 | 0.365 12 | 0.369 98 | 0.359 47 | 0.595 32 |

| k | 0.012 33 | 0.013 07 | 0.014 34 | 0.017 03 | 0.087 43 | ||

| b | 0.365 72 | 0.365 12 | 0.369 98 | 0.359 47 | 22.164 49 | ||

| g | 0.012 33 | 0.013 07 | 0.014 34 | 0.017 03 | 0.039 35 | ||

| c | 0.365 72 | 0.365 12 | 0.369 98 | 0.359 47 | -21.762 84 | ||

| h | 0.012 33 | 0.013 07 | 0.014 34 | 0.017 03 | 0.041 42 | ||

| 6 | Newton | k | 0.011 23 | 0.011 92 | 0.012 92 | 0.015 78 | 0.021 44 |

| 7 | Page | k | -0.105 99 | -0.109 21 | -0.113 68 | -0.125 64 | 0.0188 5 |

| n | -0.105 99 | -0.109 21 | -0.113 68 | -0.125 64 | 1.137 07 | ||

| 8 | Two-term Logarithmic model | a | 0.548 56 | 0.547 69 | 0.554 95 | 0.539 2 | -18.800 28 |

| K0 | 0.012 33 | 0.013 07 | 0.014 34 | 0.017 03 | 0.035 68 | ||

| b | 0.548 56 | 0.547 69 | 0.554 95 | 0.539 2 | 19.773 3 | ||

| K1 | 0.012 33 | 0.013 07 | 0.014 34 | 1.017 03 | 0.034 56 | ||

| 9 | Verma et al. | a | 1.118 35 | 1.117 63 | 1.138 21 | 1.103 26 | 55.232 05 |

| k | 0.012 57 | 0.013 34 | 0.014 7 | 0.017 43 | 0.033 94 | ||

| g | 15.304 4 | 15.714 88 | 15.856 79 | 16.038 18 | 0.034 28 | ||

| 10 | Wang and singh | a | -0.008 1 | -0.008 67 | -0.009 32 | -0.011 82 | -0.015 47 |

| b | 1.58878E-5 | 1.84101E-5 | 2.09099E-5 | 3.61915E-5 | 6.1261E-5 | ||

| 编号 No. | 模型名称 Name of model | SSE | R2 | RMSE |

|---|---|---|---|---|

| 1 | Weibull | 0.153 1 | 0.963 9 | 0.003 43 |

| 2 | Henderson and pabis | 0.107 3 | 0.974 6 | 0.002 403 |

| 3 | Logarithmic model | 0.007 7 | 0.998 1 | 0.000 535 626 |

| 4 | Midilli et al. | 0.055 4 | 0.979 6 | 0.035 4 |

| 5 | Modified enderson and pabis | 0.093 76 | 0.975 8 | 0.002 298 666 |

| 6 | Newton(single-term exponential) | 0.153 1 | 0.964 67 | 0.005 619 8 |

| 7 | Page | 0.153 06 | 0.963 86 | 0.003 682 6 |

| 8 | Two-term Logarithmic model | 0.094 8 | 0.976 66 | 0.002 224 8 |

| 9 | Verma et al. | 0.085 918 | 0.978 864 | 0.001 958 4 |

| 10 | Wang and singh | 0.010 839 6 | 0.997 265 3 | 0.001 276 6 |

表5 不同温度下10种模型拟合

Tab.5 The fitting results of 10 models at different temperatures

| 编号 No. | 模型名称 Name of model | SSE | R2 | RMSE |

|---|---|---|---|---|

| 1 | Weibull | 0.153 1 | 0.963 9 | 0.003 43 |

| 2 | Henderson and pabis | 0.107 3 | 0.974 6 | 0.002 403 |

| 3 | Logarithmic model | 0.007 7 | 0.998 1 | 0.000 535 626 |

| 4 | Midilli et al. | 0.055 4 | 0.979 6 | 0.035 4 |

| 5 | Modified enderson and pabis | 0.093 76 | 0.975 8 | 0.002 298 666 |

| 6 | Newton(single-term exponential) | 0.153 1 | 0.964 67 | 0.005 619 8 |

| 7 | Page | 0.153 06 | 0.963 86 | 0.003 682 6 |

| 8 | Two-term Logarithmic model | 0.094 8 | 0.976 66 | 0.002 224 8 |

| 9 | Verma et al. | 0.085 918 | 0.978 864 | 0.001 958 4 |

| 10 | Wang and singh | 0.010 839 6 | 0.997 265 3 | 0.001 276 6 |

| 模型参数 Parameters models | Logarithmic model | Wang and singh |

|---|---|---|

| Ranges of SSE | 0.003 7-0.013 3 | 0.002 21-0.020 9 |

| Mean value of SSE | 0.005 4 | 0.012 7 |

| Ranges of R2 | 0.999 3-0.996 9 | 0.993 2-0.999 3 |

| Mean value R2 | 0.998 1 | 0.997 3 |

| Ranges of RMSE | 0.001 8-0.008 1 | 0.005 8-0.019 2 |

| Mean value RMSE | 0.007 7 | 0.010 8 |

表6 2种模型在不同干燥条件下结果

Tab.6 Results of two models under different drying conditions

| 模型参数 Parameters models | Logarithmic model | Wang and singh |

|---|---|---|

| Ranges of SSE | 0.003 7-0.013 3 | 0.002 21-0.020 9 |

| Mean value of SSE | 0.005 4 | 0.012 7 |

| Ranges of R2 | 0.999 3-0.996 9 | 0.993 2-0.999 3 |

| Mean value R2 | 0.998 1 | 0.997 3 |

| Ranges of RMSE | 0.001 8-0.008 1 | 0.005 8-0.019 2 |

| Mean value RMSE | 0.007 7 | 0.010 8 |

| 干燥温度 Drying temperature(℃) | 线性拟合方程 Linear fitting equation | R2 | Deff×10-9 (m2/s) | |

|---|---|---|---|---|

| 干燥温度 Drying temperature | 30 | Y =-0.076 7X + 0.613 9 | R2= 0.837 2 | 4.671 0 |

| 32.5 | Y =-0.079 2X +0.466 2 | R2= 0.913 1 | 4.823 3 | |

| 35 | Y =-0.087 6X + 0.614 5 | R2= 0.850 5 | 5.334 8 | |

| 37.5 | Y =-0.092 1X + 0.288 8 | R2= 0.962 5 | 5.608 8 | |

| 40 | Y =-0.114 4X + 0.415 5 | R2= 0.957 9 | 6.966 9 |

表7 不同温度条件下葡萄果实干燥有效水分扩散系数

Tab.7 Effective moisture diffusivity of grape fruit during drying at different temperatures

| 干燥温度 Drying temperature(℃) | 线性拟合方程 Linear fitting equation | R2 | Deff×10-9 (m2/s) | |

|---|---|---|---|---|

| 干燥温度 Drying temperature | 30 | Y =-0.076 7X + 0.613 9 | R2= 0.837 2 | 4.671 0 |

| 32.5 | Y =-0.079 2X +0.466 2 | R2= 0.913 1 | 4.823 3 | |

| 35 | Y =-0.087 6X + 0.614 5 | R2= 0.850 5 | 5.334 8 | |

| 37.5 | Y =-0.092 1X + 0.288 8 | R2= 0.962 5 | 5.608 8 | |

| 40 | Y =-0.114 4X + 0.415 5 | R2= 0.957 9 | 6.966 9 |

| [1] | 马云龙, 张雯, 任艳君, 等. 葡萄干燥的研究进展[J]. 食品科技, 2022, 47(8):27-35. |

| MA Yunlong, ZHANG Wen, REN Yanjun, et al. Research progress on grape drying[J]. Food Science and Technology, 2022, 47(8):27-35. | |

| [2] | 侯旭杰, 张滨, 热衣木江, 等. 无核葡萄干护色保绿技术试验[J]. 塔里木农垦大学学报, 2000, 12(1):9-12. |

| HOU Xujie, ZHANG Bin, Reyimujiang, et al. Experiment on color protection and green preservation technology of seedless raisins[J]. Journal of Tarim Agricultural Reclamation University, 2000, 12(1):9-12. | |

| [3] |

康彦, 关志强, 李敏, 等. 预处理对无核白葡萄热风干燥特性的影响[J]. 食品科学, 2014, 35(5):119-123.

DOI |

|

KANG Yan, GUAN Zhiqiang, LI Min, et al. Effect of pretreatment on hot air drying characteristics of seedless white grapes[J]. Food Science, 2014, 35(5):119-123.

DOI |

|

| [4] | 孟阳, 刘峰娟, 王玉红, 等. 热风干燥温度对无核白葡萄干品质的影响[J]. 食品与机械, 2015, 31(1):204-207. |

| MENG Yang, LIU Fengjuan, WANG Yuhong, et al. Effect of hot air drying temperature on quality of seedless white raisins[J]. Food & Machinery, 2015, 31(1):204-207. | |

| [5] |

Wen X, Li W, Li W, et al. Quality characteristics and non-volatile taste formation mechanism of Lentinula edodes during hot air drying[J]. Food Chemistry, 2022, 393:133378.

DOI URL |

| [6] |

Pei Y S, Li Z F, Song C F, et al. Analysis and modelling of temperature and moisture gradient for ginger slices in hot air drying[J]. Journal of Food Engineering, 2022, 323:111009.

DOI URL |

| [7] |

Shi S, Feng J, An G E, et al. Dynamics of heat transfer and moisture in beef jerky during hot air drying[J]. Meat Science, 2021, 182:108638.

DOI URL |

| [8] |

Gao M Q, Wan K J, Miao Z Y, et al. Hot-air drying shrinkage process of lignite and its cracking mechanism[J]. Fuel, 2022, 316:123187.

DOI URL |

| [9] | 刘辉, 卢扬, 叶夕苗, 等. 外源硫诱导苦荞镉胁迫响应的比较转录组学分析[J]. 生物技术通报, 2023:1-15. |

| LIU Hui, LU Yang, YE Ximiao, et al. Comparative transcriptomic analysis of exogenous sulfur-induced cadmium stress response of buckwheat buckwheat[J]. Biotechnology Bulletin, 2023:1-15. | |

| [10] |

Xiao H W, Bai J W, Xie L, et al. Thin-layer air impingement drying enhances drying rate of American ginseng(Panax quinquefolium L.) slices with quality attributes considered[J]. Food and Bioproducts Processing, 2015, 94:581-591.

DOI URL |

| [11] |

Peter M, Liu Z W, Fang Y L, et al. Computational intelligence and mathematical modelling in chanterelle mushrooms’ drying process under heat pump dryer[J]. Biosystems Engineering, 2021, 212:143-159.

DOI URL |

| [12] | Niu Y, Wei S Y, Liu H, et al. The kinetics of nutritional quality changes during winter jujube slices drying process[J]. Quality Assurance and Safety of Crops & Foods, 2021, 13(1):73-82. |

| [13] |

Ortiz-RodrÍguez N M, MarÍn-Camacho J F, Llamas-Gonzalez A, et al. Drying kinetics of natural rubber sheets under two solar thermal drying systems[J]. Renewable Energy, 2021, 165:438-454.

DOI URL |

| [14] | Biswas R, Hossain M A, Zzaman W. Thin layer modeling of drying kinetics, rehydration kinetics and color changes of osmotic pre-treated pineapple(Ananas comosus)slices during drying:Development of a mechanistic model for mass transfer[J]. Innovative Food Science & Emerging Technologies, 2022, 80:103094. |

| [15] |

Masud M H, Himel H H, Arefin A M E, et al. Mathematical modelling and exergo-environmental analysis of drying potato samples in a waste heat-based convective dryer[J]. Environmental Challenges, 2021, 5:100372.

DOI URL |

| [16] | Bousselma A, Abdessemed D, Tahraoui H, et al. Artificial intelligence and mathematical modelling of the drying kinetics of pre-treated whole apricots[J]. Croatian Society of Chemical Engineers/HDKI, 2021(11112). |

| [17] |

El-Mesery H S, Sarpong F, Xu W X, et al. Design of low-energy consumption hybrid dryer:A case study of garlic(Allium sativum)drying process[J]. Case Studies in Thermal Engineering, 2022, 33:101929.

DOI URL |

| [18] |

Meng Z F, Cui X N, Zhang H, et al. Study on drying characteristics of yam slices under heat pump-electrohydrodynamics combined drying[J]. Case Studies in Thermal Engineering, 2023, 41:102601.

DOI URL |

| [19] |

Mbegbu N N, Nwajinka C O, Amaefule D O. Thin layer drying models and characteristics of scent leaves(Ocimum gratissimum)and lemon basil leaves(Ocimum africanum)[J]. Heliyon, 2021, 7(1):e05945.

DOI URL |

| [20] |

Nanvakenari S, Movagharnejad K, Latifi A. Modelling and experimental analysis of rice drying in new fluidized bed assisted hybrid infrared-microwave dryer[J]. Food Research International, 2022, 159:111617.

DOI URL |

| [21] |

Lamrani B, Elmrabet Y, Mathew I, et al. Energy, economic analysis and mathematical modelling of mixed-mode solar drying of potato slices with thermal storage loaded V-groove collector:application to Maghreb Region[J]. Renewable Energy, 2022, 200:48-58.

DOI URL |

| [22] |

Sitorus A, Novrinaldi, Putra S A, et al. Modelling drying kinetics of paddy in swirling fluidized bed dryer[J]. Case Studies in Thermal Engineering, 2021, 28:101572.

DOI URL |

| [23] | 董艳华. 无核白葡萄干燥过程特性及其变色机理研究[D]. 青岛: 中国海洋大学, 2015. |

| DONG Yanhua. Study on drying process characteristics and discoloration mechanism of seedless white grapes[D]. Qingdao: Ocean University of China, 2015. | |

| [24] | 叶令帅, 索玉静, 韩卫娟, 等. 早熟柿与晚熟柿在果实发育过程中的品质特性差异[J]. 西北农林科技大学学报(自然科学版), 2023, 51(7):83-91,106. |

| YE Lingshuai, SUO Yujing, HAN Weijuan, et al. Differences in quality characteristics between early and late ripening persimmons during fruit development[J]. Journal of Northwest A&F University(Natural Science Edition.), 2023, 51(7):83-91,106. | |

| [25] | 代羽可欣, 王宇滨, 赵文婷, 等. 热处理对鲜切马铃薯褐变及挥发性物质的影响[J]. 现代食品科技, 2022:1-8. |

| DAIYU Kexin, WANG Yubin, ZHAO Wenting, et al. Effects of heat treatment on browning and volatile substances in fresh-cut potato[J]. Modern Food Science and Technology, 2022:1-8. | |

| [26] | 黄健航, 郑峻, 杨斌, 等. 不同干燥温度对鹿茸菇品质及其抗氧化活性的比较分析[J]. 中国食品添加剂, 2022, 33(2):194-200. |

| HUANG Jianhang, ZHENG Jun, YANG Bin, et al. Comparative analysis of quality and antioxidant activity of deer antler mushroom at different drying temperatures[J]. China Food Additives, 2022, 33(2):194-200. |

| [1] | 乔雅洁, 付慧鑫, 乔雪, 孟新涛, 张婷, 潘俨. 不同贮藏温度条件下鲜牛肉品质的变化规律[J]. 新疆农业科学, 2024, 61(9): 2323-2329. |

| [2] | 胡华兵, 孙琳琳, 刘建雄, 贺碧微, 刘珣, 郇町, 李有芳. 滴灌甜菜糖分积累与温度的相关性分析[J]. 新疆农业科学, 2024, 61(8): 1916-1925. |

| [3] | 付鑫法, 吕廷波, 王久龙, 李港强, 宋仁友, 刘一凡. 春灌定额对棉田水温盐分布及棉花苗期生长发育的影响[J]. 新疆农业科学, 2024, 61(6): 1336-1344. |

| [4] | 党旭伟, 林馨园, 贺正, 陈燕, 慈宝霞, 马学花, 郭晨荔, 贺亚星, 刘扬, 马富裕. 基于无人机热红外遥感图像提取滴灌棉花冠层温度及精度评价[J]. 新疆农业科学, 2024, 61(3): 565-575. |

| [5] | 卢红琴, 白云岗, 柴仲平, 卢震林, 刘洪波, 郑明, 肖军. 拱棚环境下“干播湿出”棉田保苗技术效果评价[J]. 新疆农业科学, 2024, 61(12): 2872-2882. |

| [6] | 周小云, 张军高, 梁晶, 龚静云, 周广威, 张少民, 雷斌. 低温和水分胁迫条件下萎锈灵对棉花种子萌发及幼苗生理特性的影响[J]. 新疆农业科学, 2024, 61(12): 3051-3060. |

| [7] | 党新晨, 沈忠义, 屈冬林, 宋于洋. 不同农艺措施对霞多丽葡萄叶幕微气候的影响[J]. 新疆农业科学, 2024, 61(10): 2427-2433. |

| [8] | 刘玉芳, 张志刚, 李长城, 李宏, 程平, 杨璐. 不同温度和成熟度对杏贮藏期腐烂率和品质的影响[J]. 新疆农业科学, 2023, 60(9): 2189-2197. |

| [9] | 李雪玲, 郭俊先, 陈莉, 宋鹤岭, 张众. 不同覆膜宽度对棉花农田环境的影响[J]. 新疆农业科学, 2023, 60(8): 1840-1847. |

| [10] | 张超, 白云岗, 郑明, 肖军, 丁平. 极端干旱区葡萄水肥协同效应[J]. 新疆农业科学, 2023, 60(8): 1931-1939. |

| [11] | 来汉林, 沈煜洋, 陈利, 杨红, 李月, 雷钧杰, 李广阔, 高海峰. 温度和盐胁迫对播娘蒿种子萌发特性的影响[J]. 新疆农业科学, 2023, 60(6): 1326-1334. |

| [12] | 王文涛, 吴博, 邰红忠, 练文明, 戴翠荣, 李双江, 蒲艳梅. 新疆阿拉尔垦区不同播期对棉花生长的影响[J]. 新疆农业科学, 2023, 60(6): 1413-1422. |

| [13] | 姚庆, 阿里别里根·哈孜太, 杨明花, 李强, 苗昊翠, 崔宏亮. 藜麦种子对萌发温度的响应及低温胁迫萌发能力鉴定[J]. 新疆农业科学, 2023, 60(5): 1141-1149. |

| [14] | 何雅文, 曾斌, 李明昆, 钟海霞, 张雯, 张川, 王敏, 伍新宇, 张付春. 无核白葡萄成熟过程中果实品质涩变分析[J]. 新疆农业科学, 2023, 60(12): 2982-2992. |

| [15] | 王旭, 和海秀, 范守杰, 彭椿皓, 王瑞楠, 孟玲, 徐巧, 白如霄, 崔瑜. 生物降解地膜对甜菜生长及产量的影响[J]. 新疆农业科学, 2023, 60(11): 2735-2741. |

| 阅读次数 | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

全文 60

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

摘要 169

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||