Xinjiang Agricultural Sciences ›› 2022, Vol. 59 ›› Issue (3): 634-644.DOI: 10.6048/j.issn.1001-4330.2022.03.013

• Horticultural Special Local Products·Agricultural Product Processing • Previous Articles Next Articles

YANG Lu( ), FAN Shaoli, LI Hong, CHENG Ping, ZHANG Zhigang

), FAN Shaoli, LI Hong, CHENG Ping, ZHANG Zhigang

Received:2021-07-10

Online:2022-03-20

Published:2022-03-28

Correspondence author:

YANG Lu

Supported by:通讯作者:

杨璐

作者简介:杨璐(1985-),女,副研究员,硕士,研究方向为植物资源化学与生物活性物质,(E-mail) lycszx_article@163.com

基金资助:CLC Number:

YANG Lu, FAN Shaoli, LI Hong, CHENG Ping, ZHANG Zhigang. Optimization of Chief Fermentation Process and Quality Evaluation of Mulberry Wine Based on Response Surface Method[J]. Xinjiang Agricultural Sciences, 2022, 59(3): 634-644.

杨璐, 范少丽, 李宏, 程平, 张志刚. 基于响应面法优化桑葚果酒主发酵工艺及其品质评价[J]. 新疆农业科学, 2022, 59(3): 634-644.

| 水平编码 Horizontal coding | A | B | C |

|---|---|---|---|

| 发酵温度 Fermentation temperature (℃) | 酵母浓度 Yeast concentration (g/kg) | SO2添加量 SO2 addition (mg/kg) | |

| -1 | 16~18 | 0.1 | 30 |

| 0 | 20~22 | 0.2 | 50 |

| 1 | 24~26 | 0.3 | 80 |

Table 1 factors of box-behnken scheme design and horizontal coding

| 水平编码 Horizontal coding | A | B | C |

|---|---|---|---|

| 发酵温度 Fermentation temperature (℃) | 酵母浓度 Yeast concentration (g/kg) | SO2添加量 SO2 addition (mg/kg) | |

| -1 | 16~18 | 0.1 | 30 |

| 0 | 20~22 | 0.2 | 50 |

| 1 | 24~26 | 0.3 | 80 |

| 升温速率 Heating rate (℃/min) | 温度 Temperature (℃) | 保持时间 Holding time (min) |

|---|---|---|

| / | 50 | 2 |

| 5 | 120 | 2 |

| 6 | 250 | 10 |

Table 2 Chromatographic conditions: heating procedure

| 升温速率 Heating rate (℃/min) | 温度 Temperature (℃) | 保持时间 Holding time (min) |

|---|---|---|

| / | 50 | 2 |

| 5 | 120 | 2 |

| 6 | 250 | 10 |

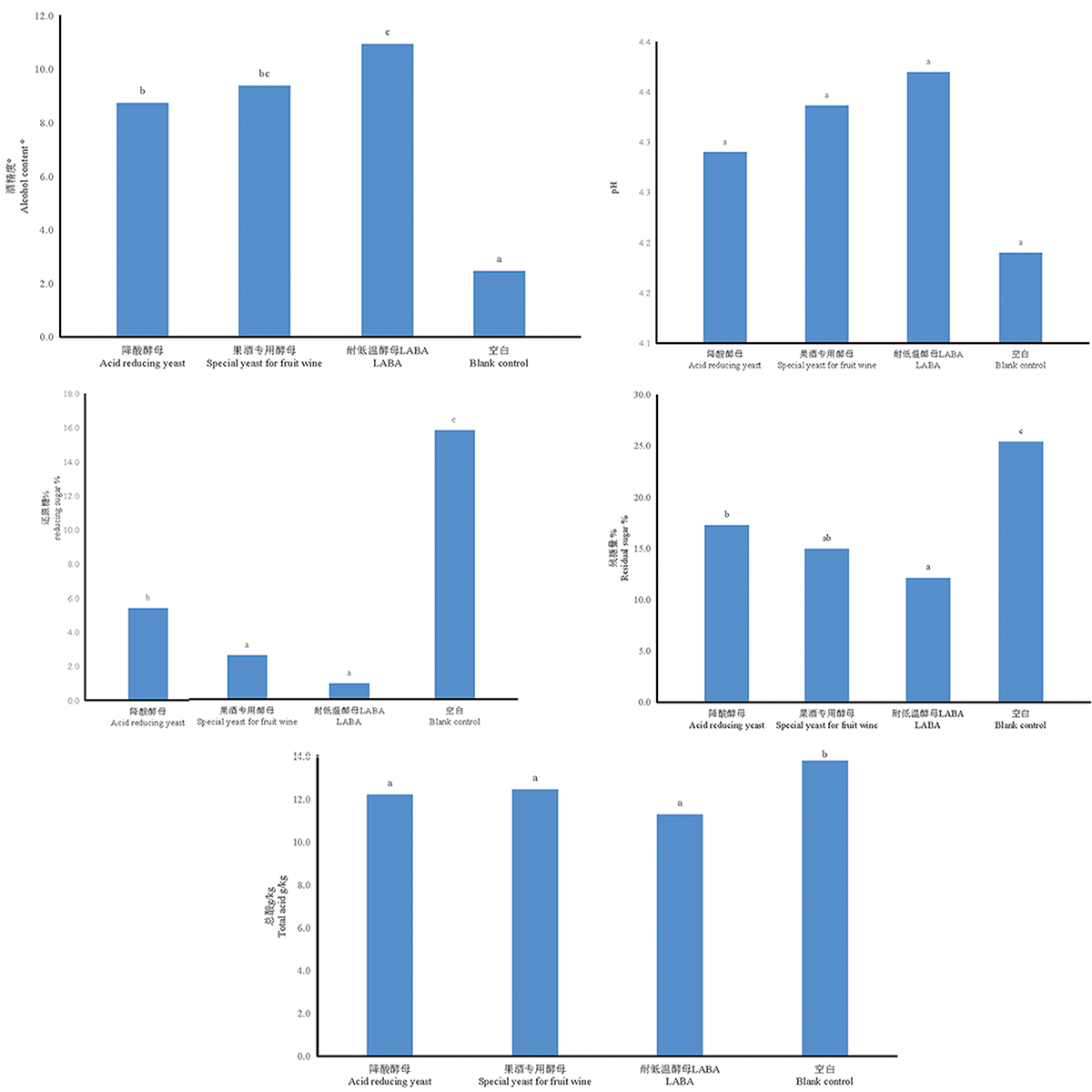

Fig.1 Effect of yeast varieties on the alcohol content, pH value, reducing sugar, residual sugar content, total acid of mulberry wine Note: There are significant differences in the expression of different lowercase letters (P < 0.05), the same as below

| 序号 No. | A酵母浓度 Yeast concentration (g/kg) | B发酵温度 Fermentation temperature(℃) | CSO2添加量 SO2 dosage (mg/kg) | 酒精度 Alcohol content (%vol) |

|---|---|---|---|---|

| 1 | -1 | 0 | -1 | 10.2 |

| 2 | 1 | 0 | 1 | 10.9 |

| 3 | 1 | -1 | 0 | 9.8 |

| 4 | -1 | 1 | 0 | 10.6 |

| 5 | 0 | 0 | 0 | 11.2 |

| 6 | 0 | -1 | 1 | 10.3 |

| 7 | 0 | 0 | 0 | 11.4 |

| 8 | 0 | 1 | 1 | 11.1 |

| 9 | 1 | 0 | -1 | 10.7 |

| 10 | -1 | -1 | 0 | 9.6 |

| 11 | 0 | 1 | -1 | 11.5 |

| 12 | -1 | 0 | 1 | 11.5 |

| 13 | 0 | 0 | 0 | 11.2 |

| 14 | 0 | 0 | 0 | 11.3 |

| 15 | 1 | 1 | 0 | 11.0 |

| 16 | 0 | -1 | -1 | 9.8 |

| 17 | 0 | 0 | 0 | 11.3 |

Table 3 Design and results of response interview experiments

| 序号 No. | A酵母浓度 Yeast concentration (g/kg) | B发酵温度 Fermentation temperature(℃) | CSO2添加量 SO2 dosage (mg/kg) | 酒精度 Alcohol content (%vol) |

|---|---|---|---|---|

| 1 | -1 | 0 | -1 | 10.2 |

| 2 | 1 | 0 | 1 | 10.9 |

| 3 | 1 | -1 | 0 | 9.8 |

| 4 | -1 | 1 | 0 | 10.6 |

| 5 | 0 | 0 | 0 | 11.2 |

| 6 | 0 | -1 | 1 | 10.3 |

| 7 | 0 | 0 | 0 | 11.4 |

| 8 | 0 | 1 | 1 | 11.1 |

| 9 | 1 | 0 | -1 | 10.7 |

| 10 | -1 | -1 | 0 | 9.6 |

| 11 | 0 | 1 | -1 | 11.5 |

| 12 | -1 | 0 | 1 | 11.5 |

| 13 | 0 | 0 | 0 | 11.2 |

| 14 | 0 | 0 | 0 | 11.3 |

| 15 | 1 | 1 | 0 | 11.0 |

| 16 | 0 | -1 | -1 | 9.8 |

| 17 | 0 | 0 | 0 | 11.3 |

| 方差来源 | 平方和 | 自由度 | 均方 | F值 | P值 | 显著性 |

|---|---|---|---|---|---|---|

| 模型 Model | 6.05 | 9 | 0.67 | 13.62 | 0.001 2 | |

| A-酵母浓度Yeast concentration | 0.031 | 1 | 0.031 | 0.63 | 0.452 3 | |

| B-发酵温度Fermentation temperature | 2.76 | 1 | 2.76 | 55.94 | 0.000 1 | |

| C-SO2添加量Content of SO2 | 0.32 | 1 | 0.32 | 6.48 | 0.038 3 | * |

| AB | 1.00E-02 | 1 | 1.00E-02 | 0.2 | 0.666 2 | |

| AC | 0.3 | 1 | 0.3 | 6.13 | 0.042 5 | * |

| BC | 0.2 | 1 | 0.2 | 4.1 | 0.082 5 | |

| A^2 | 0.82 | 1 | 0.82 | 16.52 | 0.004 8 | |

| B^2 | 1.47 | 1 | 1.47 | 29.7 | 0.001 | |

| C^2 | 9.47E-04 | 1 | 9.47E-04 | 0.019 | 0.893 7 | |

| 残差 Residual | 0.35 | 7 | 0.049 | |||

| 失拟项 Lack of Fit | 0.32 | 3 | 0.11 | 15.12 | 0.012 | * |

| 纯误差Pure Error | 0.028 | 4 | 7.00E-03 | |||

| 总和Cor Total | 6.4 | 16 |

Table 4 Experimental results regression model variance analysis

| 方差来源 | 平方和 | 自由度 | 均方 | F值 | P值 | 显著性 |

|---|---|---|---|---|---|---|

| 模型 Model | 6.05 | 9 | 0.67 | 13.62 | 0.001 2 | |

| A-酵母浓度Yeast concentration | 0.031 | 1 | 0.031 | 0.63 | 0.452 3 | |

| B-发酵温度Fermentation temperature | 2.76 | 1 | 2.76 | 55.94 | 0.000 1 | |

| C-SO2添加量Content of SO2 | 0.32 | 1 | 0.32 | 6.48 | 0.038 3 | * |

| AB | 1.00E-02 | 1 | 1.00E-02 | 0.2 | 0.666 2 | |

| AC | 0.3 | 1 | 0.3 | 6.13 | 0.042 5 | * |

| BC | 0.2 | 1 | 0.2 | 4.1 | 0.082 5 | |

| A^2 | 0.82 | 1 | 0.82 | 16.52 | 0.004 8 | |

| B^2 | 1.47 | 1 | 1.47 | 29.7 | 0.001 | |

| C^2 | 9.47E-04 | 1 | 9.47E-04 | 0.019 | 0.893 7 | |

| 残差 Residual | 0.35 | 7 | 0.049 | |||

| 失拟项 Lack of Fit | 0.32 | 3 | 0.11 | 15.12 | 0.012 | * |

| 纯误差Pure Error | 0.028 | 4 | 7.00E-03 | |||

| 总和Cor Total | 6.4 | 16 |

| 序号 No. | 香气化合物 Aroma compounds | 保留时间 Retention time (min) | 含量 Content (%) | 气味描述 Odor description |

|---|---|---|---|---|

| A | 酯类 | |||

| 1 | 己酸乙酯 | 9.311 | 8.483 | 果香、草莓香[ |

| 2 | 琥珀酸氢乙酯 | 14.350 | 0.477 | / |

| 3 | 丁二酸二乙酯 | 14.678 | 4.786 | / |

| 4 | 辛酸乙酯 | 15.185 | 9.659 | 果香、奶油味[ |

| 5 | 甘油1,2-二乙酸酯 | 16.436 | 0.343 | / |

| 6 | 苯乙酸乙酯 | 16.488 | 0.304 | 蜂蜜香[ |

| 7 | 乙酸苯乙酯 | 16.835 | 0.459 | 玫瑰、茉莉花香[ |

| 8 | 壬酸乙酯 | 17.963 | 0.602 | 酒心巧克力香味 |

| 9 | 苯丙酸乙酯 | 19.417 | 8.291 | 草莓香、奶酪味[ |

| 10 | 癸酸乙酯 | 20.657 | 20.163 | 奶油味、果香[ |

| 12 | 月桂酸乙酯 | 25.560 | 16.716 | 甜香、蜂蜡香[ |

| 13 | 苯甲酸乙基己酯 | 28.139 | 0.224 | / |

| 14 | 肉豆蔻酸乙酯 | 29.970 | 4.423 | 椰子、蜂蜡香[ |

| 15 | 棕榈酸乙酯 | 34.001 | 2.705 | 水果味、奶油味[ |

| 序号 No. | 香气化合物 Aroma compounds | 保留时间 Retention time (min) | 含量 Content (%) | 气味描述 Odor description |

| 16 | 亚油酸乙酯 | 37.084 | 0.226 | / |

| B | 醇类 | |||

| 17 | 乙醇 | 1.133 | 17.972 | / |

| 18 | 苯乙醇 | 12.717 | 1.094 | 玫瑰花香、甜香[ |

| C | 酸类 | |||

| 19 | 己酸 | 8.823 | 0.777 | 乳酪、甜香[ |

| 20 | 辛酸 | 14.457 | 0.603 | 脂肪味、奶油味[ |

| F | 其他 | |||

| 21 | 2,3-二氢-3,5-二羟基-6-甲基-4H-吡喃-4-酮 | 13.574 | 0.574 | / |

| 22 | 丁香酚 | 19.502 | 0.433 | 丁香香气[ |

| 23 | 二氢大马酮 | 20.234 | 0.354 | / |

| 24 | 4-羟基-4-甲基-4H-萘-1-酮 | 20.391 | 0.331 | / |

Table 5 GC-MS analysis of volatile aroma compounds

| 序号 No. | 香气化合物 Aroma compounds | 保留时间 Retention time (min) | 含量 Content (%) | 气味描述 Odor description |

|---|---|---|---|---|

| A | 酯类 | |||

| 1 | 己酸乙酯 | 9.311 | 8.483 | 果香、草莓香[ |

| 2 | 琥珀酸氢乙酯 | 14.350 | 0.477 | / |

| 3 | 丁二酸二乙酯 | 14.678 | 4.786 | / |

| 4 | 辛酸乙酯 | 15.185 | 9.659 | 果香、奶油味[ |

| 5 | 甘油1,2-二乙酸酯 | 16.436 | 0.343 | / |

| 6 | 苯乙酸乙酯 | 16.488 | 0.304 | 蜂蜜香[ |

| 7 | 乙酸苯乙酯 | 16.835 | 0.459 | 玫瑰、茉莉花香[ |

| 8 | 壬酸乙酯 | 17.963 | 0.602 | 酒心巧克力香味 |

| 9 | 苯丙酸乙酯 | 19.417 | 8.291 | 草莓香、奶酪味[ |

| 10 | 癸酸乙酯 | 20.657 | 20.163 | 奶油味、果香[ |

| 12 | 月桂酸乙酯 | 25.560 | 16.716 | 甜香、蜂蜡香[ |

| 13 | 苯甲酸乙基己酯 | 28.139 | 0.224 | / |

| 14 | 肉豆蔻酸乙酯 | 29.970 | 4.423 | 椰子、蜂蜡香[ |

| 15 | 棕榈酸乙酯 | 34.001 | 2.705 | 水果味、奶油味[ |

| 序号 No. | 香气化合物 Aroma compounds | 保留时间 Retention time (min) | 含量 Content (%) | 气味描述 Odor description |

| 16 | 亚油酸乙酯 | 37.084 | 0.226 | / |

| B | 醇类 | |||

| 17 | 乙醇 | 1.133 | 17.972 | / |

| 18 | 苯乙醇 | 12.717 | 1.094 | 玫瑰花香、甜香[ |

| C | 酸类 | |||

| 19 | 己酸 | 8.823 | 0.777 | 乳酪、甜香[ |

| 20 | 辛酸 | 14.457 | 0.603 | 脂肪味、奶油味[ |

| F | 其他 | |||

| 21 | 2,3-二氢-3,5-二羟基-6-甲基-4H-吡喃-4-酮 | 13.574 | 0.574 | / |

| 22 | 丁香酚 | 19.502 | 0.433 | 丁香香气[ |

| 23 | 二氢大马酮 | 20.234 | 0.354 | / |

| 24 | 4-羟基-4-甲基-4H-萘-1-酮 | 20.391 | 0.331 | / |

| 项目 Project | 测定结果 Determination results | |

|---|---|---|

| pH | 4.11±0.02 | |

| 色差 Chromatic aberration | L值 | 22.3±0.6 |

| a值 | 3.3±2.1 | |

| b值 | -6.3±1.5 | |

| 可溶性固形物 Soluble solids (%) | 12.27±0.06 | |

| 总糖 Total sugar (g/L) | 20.22±0.77 | |

| 可滴定酸 Total acid (g/L) | 13.26±0.03 | |

| 酒精度 Alcohol content (%vol) | 11.3±0.29 | |

| 总酚 Total phenols (g GAE/L) | 17.29±0.22 | |

| 总黄酮 Total flavonoids (g/L) | 2.66±0.06 | |

| 花色苷 Anthocyanins (g/L) | 0.34±0.04 | |

Table 6 Results of physical and chemical indexes of mulberry wine

| 项目 Project | 测定结果 Determination results | |

|---|---|---|

| pH | 4.11±0.02 | |

| 色差 Chromatic aberration | L值 | 22.3±0.6 |

| a值 | 3.3±2.1 | |

| b值 | -6.3±1.5 | |

| 可溶性固形物 Soluble solids (%) | 12.27±0.06 | |

| 总糖 Total sugar (g/L) | 20.22±0.77 | |

| 可滴定酸 Total acid (g/L) | 13.26±0.03 | |

| 酒精度 Alcohol content (%vol) | 11.3±0.29 | |

| 总酚 Total phenols (g GAE/L) | 17.29±0.22 | |

| 总黄酮 Total flavonoids (g/L) | 2.66±0.06 | |

| 花色苷 Anthocyanins (g/L) | 0.34±0.04 | |

| [1] | 杨璐, 卢晓丽, 程平, 等. 基于灰色关联度和主成分分析法的桑葚品质综合评价体系构建[J]. 新疆农业科学, 2017(5): 862-870. |

| YANG Lu, LU Xiaoli, CHENG Ping, et al. Establishing Comprehensive Evaluation System for Mulberry Based on Grey Relational Grade Analysis and Principal Component Analysis[J]. Xinjiang Agricultural Sciences, 2017,(5): 862-870. | |

| [2] | 王贺, 韩爱芝, 贾清华, 等. 新疆药桑和黑桑营养成分及活性成分分析[J]. 食品科学, 2016, 37(8): 91-96. |

| WANG He, HAN Aizhi, JIA Qinghua, et al. Analysis of Nutrient Components and Active Ingredients of Morusnigra L. and M.alba L.var.tatarica in Xinjiang Autonomous Region[J]. Food Science, 2016, 37(8): 91-96. | |

| [3] | 张荷兰, 陆鸿奎, 郭晓敏, 等. 桑葚保健食品的研究与分析[J]. 食品与发酵科技, 2018, 54(5): 125-128. |

| ZHANG Helan, LU Hongkui, GUO Xiaomin, et al. Research and Analysis of Mulberry Health Food[J]. Food and Fermentation Sciences & Technology, 2018, 54(5): 125-128. | |

| [4] | Sun Z, Li L I, Wenfang M A. Research and Prospect of Mulberry (Morus alba L.)[J]. Agricultural Biotechnology, 2019, 8(4): 136-139. |

| [5] | 叶学林, 程水明, 温露文, 等. 响应面法优化桑葚果酒发酵工艺[J]. 中国酿造, 2017, 36(12): 105-109. |

| YE Xuelin, CHENG Shuiming, WEN Luwen, et al. Optimization of fermentation technology for mulberry wine by response surface methodology[J]. Agricultural Biotechnology, 2017, 36(12): 105-109. | |

| [6] | 杨芳, 王中兴, 王克刚, 等. 星点设计-响应面法优化桑葚果酒发酵工艺[J]. 酿酒科技, 2017,(12): 21-26. |

| YANG Fang, WANG Zhongxing, WANG Kegang, et al. Optimization of the Fermentation Process of Mulberry Wine by Central Composite Design-Response Surface Method[J]. Liquor-Making Science & Technology, 2017,(12): 21-26. | |

| [7] | 王婷, 毛亮, 雷静, 等. 优质桑葚酒酿造工艺的研究[J]. 酿酒科技, 2015,(1): 86-88, 92. |

| WANG Ting, MAO Liang, LEI Jing, et al. The Producing Techniques of Quality Mulberry Wine[J]. Liquor-Making Science & Technology, 2015,(1): 86-88, 92. | |

| [8] | 孔瑾, 李双银, 娄文娟, 等. 生料法制取山楂发酵果酒及果醋工艺技术研究[J]. 食品研究与开发, 2016, 37(17): 92-97. |

| KONG Jin, LI Shuangyin, LOU Wenjuan, et al. Study on the Process of Hawthorn Vinegar and Hawthorn Wine[J]. Food Research and Development, 2016, 37(17): 92-97. | |

| [9] | 高海生, 蔺毅峰, 李春华, 等. 干红毛樱桃酒酿造工艺研究[J]. 中国食品学报, 2002,(1): 17-21. |

| GAO Haisheng, LIN Yifeng, LI Chunhua, et al. Study on the Technique of Producing "Prunus tomentosa Thunb" Wine[J]. Journal of Chinese Institute of Food Science and Technology, 2002,(1): 17-21. | |

| [10] | 杨宁, 王伟明, 姚琳, 等. 3,5-二硝基水杨酸法测定发酵型果露酒中总糖含量[J]. 中国酿造, 2018, 37(1): 181-184. |

| YANG Ning, WANG Weiming, YAO Lin, DONG Kun. Determination of total sugar content in fermented fruit wine by 3,5-dinitrosalicylic acid method[J]. China Brewing, 2018, 37(1): 181-184. | |

| [11] | GBT 12456-2008. 食品中总酸的测定[S]. |

| GBT 12456-2008. Determination of total acid in foods[S]. | |

| [12] | 张红娟. 陕西关中平原与渭北旱塬生态区红色酿酒葡萄品质研究[D]. 杨凌:西北农林科技大学, 2018. |

| ZHANG Hongjuan. Study on the quality of red wine grape in Shaanxi Guanzhong Plain and Weibei dryland ecological region[D]. Yangling: Northwest A&F University, 2018. | |

| [13] | 李傲然, 胡倬瑜, 杨宁, 等. 银杏大麦酒的酿造工艺及品质分析[J]. 中国酿造, 2019, 38(1): 200-206. |

| LI Aoran, HU Zhuoyu, YANG Ning, et al. Brewing process and quality analysis of ginkgo-barley wine[J]. China Brewing, 2019, 38(1): 200-206. | |

| [14] | 郭浩然, 郑心怡, 张静, 等. 桑葚酒中花青素含量的测定方法优化[J]. 食品工业科技, 2020, 41(9): 255-259. |

| GUO Haoran, ZHENG Xinyi, ZHANG Jing, et al. Optimization of Determination Method of Anthocyanin Content in Mulberry Wine[J]. Science and Technology of Food Industry, 2020, 41(9): 255-259. | |

| [15] | 蔡德萍, 谈安群, 孙志高, 等. 不同脱气温度下溶解氧含量对非浓缩还原橙汁品质的影响[J]. 食品与发酵工业, 2019, 45(20): 169-175. |

| CAI Deping, TAN Anqun, SUN Zhigao, et al. Effect of dissolved oxygen content on the quality of NFC orange juice degassed at different temperatures[J]. Food and Fermentation Industries, 2019, 45(20): 169-175. | |

| [16] | 鲁榕榕, 马腾臻, 张波, 等. 不同澄清剂对起泡葡萄酒原酒的澄清作用及对香气品质的影响[J]. 食品科学, 2018, 39(12): 146-153. |

| LU Rongrong, MA Tengzhen, ZHANG Bo, et al. Effect of Different Clarifying Agents on Clarification and Aroma Quality of Sparkling Base Wine[J]. Food Science, 2018, 39(12): 146-153. | |

| [17] | 陈霞, 李敏, 张波, 等. 扩展青霉对‘蛇龙珠’葡萄酒棒曲霉素及风味品质的影响[J]. 食品科学, 2016, 37(20): 126-133. |

|

CHEN Xia, LI Min, ZHANG Bo, et al. Effect of Penicillium expansum Infection of Grapes on Patulin Content and Flavor Quality of Cabernet Gernischt Wine[J]. Food Science, 2016, 37(20): 126-133.

DOI URL |

|

| [18] | Englezos V, Torchio F, Cravero F, et al. Aroma profile and composition of Barbera wines obtained by mixed fermentations of Starmerella bacillaris (synonym Candida zemplinina) and Saccharomyces cerevisiae[J]. LWT-Food Science and Technology, 2016, (73): 567-575. |

| [19] | 谢春梅, 焦红茹, 曹芳玲. 宁夏青铜峡小产区不同品种干红葡萄酒的香气成分分析[J]. 中国酿造, 2018, 37(1): 170-176. |

| XIE Chunmei, JIAO Hongru, CAO Fangling. Analysis on aroma components of dry red wines with different varieties of grape from Ningxia Qingtongxia region[J]. China Brewing, 2018, 37(1): 170-176. | |

| [20] | 丁吉星, 何玉云, 梁艳英, 等. 新型嘉宝果起泡酒香气成分及特征香气分析[J]. 食品科学, 2014, 35(24): 145-150. |

| DING Jixing, HE Yuyun, LIANG Yanying, et al. Analysis of Volatile Aroma Compounds and Aromatic Characteristics from Jaboticaba Sparkling Wine[J]. Food Science, 2014, 35(24): 145-150. | |

| [21] | 周强, 沈旭, 付梦, 等. 炒制与烤制工艺对洽洽香瓜子呈香组分的影响[J]. 食品工业, 2017, 38(1): 53-57. |

| ZHOU Qiang, SHEN Xu, FU Meng, et al. Effect of Frying and Roasting Processing Technologies on Aroma Components in Chacheer Aromatic Sunflower Seeds[J]. Food Industry, 2017, 38(1): 53-57. |

| [1] | JIN Juan, LI lili, YANG Lei, FAN Dingyu, HAO Qing. Analysis on the Development status of Xinjiang Jujube Industry [J]. Xinjiang Agricultural Sciences, 2024, 61(S1): 106-110. |

| [2] | WU Yating, CHEN He, ZHENG Nan, MA Xianlan, ZHOU Lina, ZHAO Yankun. Current situation and development trend prospect of Xinjiang characteristic dairy industry [J]. Xinjiang Agricultural Sciences, 2024, 61(S1): 158-162. |

| [3] | XIE Ganggang, Nilufar Dlxat, WANG Xiuying, ZHANG Yuxue, ZHENG Feng, LUO Liping, FENG Yaozu, CHEN Xunji, WANG Jian. Practice And Thinking On The Cultivation Of Innovative Agricultural Young Scientific And Technological Talents [J]. Xinjiang Agricultural Sciences, 2024, 61(S1): 175-180. |

| [4] | XU Le, XIAO Hailong, ZHA Zhihao, YANG Haoran, LIU Tingting, CHEN Keke, DING Wanyue, WANG Penghao, Renaguli Yunusi. Analysis of the current situation of cooperation between research institutes and universities [J]. Xinjiang Agricultural Sciences, 2024, 61(S1): 186-190. |

| [5] | HOU Xianzheng, XIAO Tong, CHEN Yulan, WEI Jiyu. The spatial effects and mechanism of digital technology innovation on agricultural economic resilience [J]. Xinjiang Agricultural Sciences, 2024, 61(S1): 196-205. |

| [6] | LI Yunyun, Hudejiang Yusufujiang, GAO Yuan, LI Zhi, ZHAO Xin, SU Wuzheng. Scientific and technological innovation supports the analysis of the path of revitalization of rural industries [J]. Xinjiang Agricultural Sciences, 2024, 61(S1): 232-237. |

| [7] | YUE Rongqiang, ZHANG Qiong, WANG Fang, DENG Wenwen, CHEN Yu, Maiwulanjiang Mamut, Nurmanquli Batur. Improve the academic quality and influence of agricultural academic journals [J]. Xinjiang Agricultural Sciences, 2024, 61(S1): 256-260. |

| [8] | WANG Junduo, CUI Yujiang, LIANG Yajun, GONG Zhaolong, ZHENG Junyun, LI Xueyuan. Xinjiang cotton production advantageous regional layout scheme [J]. Xinjiang Agricultural Sciences, 2024, 61(S1): 60-69. |

| [9] | ZHENG Juyun, GONG Zhaolong, LIANG Yajun, GENG Shiwei, SUN Fenglei, YANG ni, LI Xueyuan, WANG Junduo. Key technology model of machine-picked cotton production in Xinjiang [J]. Xinjiang Agricultural Sciences, 2024, 61(S1): 70-74. |

| [10] | FANG Hui, DING Yindeng, FAN Guiqiang, GAO Yonghong, HUANG Tianrong. Research report on the development status of wheat industry in southern Xinjiang [J]. Xinjiang Agricultural Sciences, 2024, 61(S1): 75-80. |

| [11] | YANG Minghua, LIAO Biyong, LIU Qiang, PENG Yuncheng, Dawulai Jiekeshan, FENG Guorui, TANG Shimin. Study on variation of grain nutritional quality of glutinous maize [J]. Xinjiang Agricultural Sciences, 2024, 61(9): 2087-2093. |

| [12] | ZHANG Zehua, YE Hanchun, WANG Zhenhua, LI Wenhao, LI Haiqiang, LIU Jian. Effects of equal nitrogen applied with urease inhibitor on cotton growth, yield, and quality under mulched drip irrigation [J]. Xinjiang Agricultural Sciences, 2024, 61(9): 2103-2111. |

| [13] | CHEN Ruijie, LUO Linyi, RUAN Xiangyang, YE Jun. Effects of humic acid on soil nutrients, cotton yield and quality in cotton fields under drip irrigation [J]. Xinjiang Agricultural Sciences, 2024, 61(9): 2112-2121. |

| [14] | LIU Jing, DU Mingchuan, ZHANG Wenting, BAO Haijuan, JING Meiling, DU Wenhua. Screening of triticale germplasm in different areas of Qinghai [J]. Xinjiang Agricultural Sciences, 2024, 61(9): 2183-2190. |

| [15] | TIAN Haiyan, ZHANG Zhanqin, XIE Jianhui, WANG Jianjiang, YANG Xiangkun. Study on the relationship between Lycopene and main quality characters of processing tomato [J]. Xinjiang Agricultural Sciences, 2024, 61(9): 2197-2202. |

| Viewed | ||||||||||||||||||||||||||||||||||||||||||||||||||

|

Full text 61

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

Abstract 260

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||